Unveiling the Truth: Rust on Your Air Conditioner Condenser

Air conditioner condenser rust is a critical issue affecting the system’s efficiency and lifespan. This corrosion can reduce the condenser’s ability to transfer heat effectively, potentially resulting in system failures.

This article aims to provide critical insights into how rust develops on air conditioner condensers, its effects on the unit’s cooling capabilities, and strategies to prevent its occurrence. Gaining knowledge about air conditioner condenser rust is vital in ensuring your cooling system operates at its best and enjoys an extended service life.

Understanding Air Conditioner Condenser Rust: Key Insights for Optimal Performance

Contents

First, we’ll delve into the reasons behind air conditioner condenser rust formation. We will examine how this rust impacts the efficiency of your AC unit, outline the methods professionals use to remove air conditioner condenser rust, and provide practical advice on how to prevent future rust formation.

Common Reasons for Rust Formation on AC Condensers

Rust, or iron oxide, forms through a chemical interaction involving iron, oxygen, and moisture. Various elements can trigger rust development on an air conditioner condenser. The primary causes are:

Air Conditioner Moisture Exposure

Being exposed to air moisture, condenser coils can accumulate water. If this water remains on the coils for extended periods, it can initiate rusting.

Corrosive Settings

Installation in areas with heavy pollutants, chemicals, or near saltwater significantly raises the risk of rust formation on the condenser.

Neglected Air Conditioner Maintenance

Inadequate or sporadic upkeep leads to dirt, debris, and moisture buildup, fostering a rust-friendly environment on the condenser.

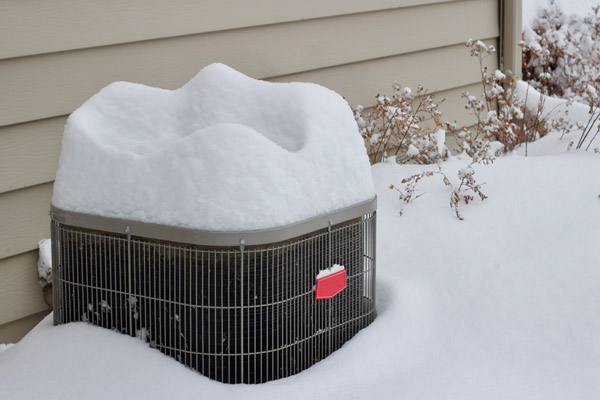

Elemental AC Unit Exposure

Condensers are outdoors, facing various weather challenges like rain, snow, and extreme temperatures. All of these can hasten the rusting process.

Physical A/C Unit Damage

Dents, scratches, or other physical harm can breach the condenser’s protective layer, exposing the underlying metal to rusting risks.

Don’t let rust compromise your AC’s performance – reach out to Point Bay Fuel for top-notch HVAC services and reliable solutions.

Impact of Rust on Air Conditioning System Performance

Rust significantly influences the cooling capacity of AC systems, particularly in these aspects:

- Decreased Heat Transfer: Rust on the condenser coils forms an obstructive layer between the air and the refrigerant. This layer acts as an insulator, impeding the crucial heat transfer process. Due to this insulation effect, the condenser’s efficiency in releasing heat is considerably reduced. This leads to a notable decline in the system’s overall cooling ability.

- Disrupted Airflow: Rust can distort or obstruct the condenser’s fins or blades, causing airflow through the coils to be restricted. This limitation hinders the system’s ability to effectively disperse heat, thus compromising its cooling efficiency. The result is a diminished capacity to maintain set temperatures.

- Increased System Strain: Rust-induced inefficiencies in heat transfer and airflow force the air conditioning system to operate longer and exert more effort to cool effectively. This extended operation escalates energy consumption and subjects the system to extra stress. Continuous overworking can lead to more frequent system malfunctions or even complete breakdowns.

- Reduced Lifespan: Rust expedites the corrosion process, leading to sustained damage in the condenser. It weakens the structural integrity of the coils and other vital components, thereby curtailing the overall service life of the air conditioning system.

An HVAC Professional’s Method for Rust Removal from Your Outdoor AC Unit

Addressing rust on an AC condenser is a delicate task that demands the right skills and tools. It’s crucial to entrust this job to qualified HVAC professionals to ensure it’s done safely and thoroughly. DIY attempts can exacerbate the problem or create safety risks. Here’s a breakdown of the process an HVAC company typically follows to tackle rust on your AC condenser:

- Detailed Inspection: The HVAC technician begins with a comprehensive evaluation of the condenser to gauge the rust’s severity. This assessment helps determine whether the rust is surface-level or has led to more profound structural or operational damage.

- Specialized Rust Treatment: The expert employs various methods tailored to the rust’s intensity. Options include using rust dissolvers, rust converters, or abrasive methods to eradicate rust. This delicate step requires skilled handling to prevent damage to the condenser’s sensitive components.

- Application of Protective Coating: Post rust removal, the technician applies a protective coating or paint to the condenser. This layer shields against moisture and environmental elements, preventing future rust formation.

- Internal Component Check and Replacement: The HVAC expert thoroughly examines the condenser’s internal parts to assess any rust-induced damage. They may suggest replacements for components like coils or fins that are significantly affected to ensure the system’s peak performance and efficiency.

- Maintenance Advice for Rust Prevention: The contractor will guide routine maintenance practices following the rust treatment. These include regular cleaning, periodic inspections, and ensuring proper drainage, all aimed at reducing moisture buildup and averting rust in the future.

Ensure your cooling system’s efficiency and longevity – trust Point Bay Fuel’s professional technicians for rust removal and preventive maintenance.

Strategies to Prevent Air Conditioner Condenser Rust

Proactive measures can greatly minimize rust formation and impact your AC system’s functionality and lifespan. Consider these effective strategies:

Routine Air Conditioning Maintenance

Regularly schedule professional HVAC maintenance to check the condenser for signs of rust or corrosion. These experts can conduct essential repairs, clean the coils in-depth, and offer advice to avert future rust issues, thereby maintaining the unit’s optimal performance.

Consistent Air Conditioner Cleaning

Regular cleaning of the condenser coils and fins is essential. This removes dirt, debris, and other elements that can retain moisture and hasten rust development. For gentle cleaning, use a soft brush or vacuum. Alternatively, for a comprehensive and expert approach, employing an HVAC technician is advisable to ensure optimal results.

Efficient AC Unit Drainage

Ensure that the condensate drain lines are unobstructed and working effectively. An HVAC technician can proficiently handle this task. Proper drainage avoids water buildup around the condenser, lowering the likelihood of rust.

Application of Protective Coatings

Use corrosion-resistant sprays or protective coatings on the condenser’s metal surfaces to create a moisture and rust-resistant barrier. For the best fit for your condenser model, seek advice from a professional on appropriate treatments or coatings.

Installation of a Shelter or Enclosure

Consider setting up a shelter or enclosure for the condenser unit to guard against direct exposure to harsh weather elements like snow, rain, or intense sunlight. This can significantly reduce moisture accumulation and enhance the unit’s durability. However, consulting an HVAC expert ensures the enclosure doesn’t impede the unit’s airflow.

Strategic Location Selection

When installing the condenser, opt for a spot that limits exposure to corrosive surroundings like high pollution, chemical-rich areas, or near salt water. This reduces the risk of accelerated rust formation.

Timely Air Conditioner Repairs

Act quickly upon noticing any rust or corrosion on the condenser. Enlist your HVAC technician to repair or replace affected parts immediately. This proactive approach prevents further rust development and averts possible system breakdowns.

Addressing rust on your AC condenser is crucial – rely on Point Bay Fuel’s expertise to keep your cooling system running smoothly.

Conclusion

Addressing rust on your AC condenser is essential for maintaining its efficiency and prolonging lifespan. Rust affects heat transfer and cooling capacity significantly. While DIY methods have their place, the expertise of an HVAC professional is crucial.

They can safely and effectively handle rust removal, assess damage, perform repairs, and offer preventive advice. Entrusting this task to a professional ensures thorough care, preventing further damage and enhancing your AC system’s performance and longevity.

Contact Point Bay Fuel for Expert HVAC Services

Point Bay Fuel is the go-to heating and cooling service provider in Ocean County and Monmouth County, New Jersey. Our professionally certified technicians are experts in HVAC tune-ups, repairs, installations, and replacements and are committed to delivering exceptional quality.

We understand the value of a comfortable, energy-efficient home, offering competitive pricing and maintenance services designed to enhance comfort and reduce costs. Our experts provide tailored solutions that respect your budget, backed by a satisfaction guarantee. For free in-home estimates and top-notch HVAC services, call Point Bay Fuel – where exceeding your expectations is our standard.

Contact us now by calling (732) 349-5059 to speak to one of our home comfort specialists! Click the link to view our service area.

Related Articles: