Boiler Efficiency: The Impact of System Water Quality

The effectiveness of boilers in homes, crucial for its influence on energy expenses and ecological impact, mirrors a boiler’s capacity to transform fuel into heat. Enhanced boiler efficiency not only leads to reduced energy expenditure and a lesser environmental impact. Interestingly enough, its efficiency is also greatly affected by the quality of water used.

Contaminants such as minerals, gases, and organic substances in the water can lead to issues like scaling, corrosion, and foaming, which negatively impact the boilers’ performance. Hence, homeowners need to comprehend and regulate water quality to ensure the peak efficiency of their boiler.

Fundamentals of Boiler Functionality

Contents

- Fundamentals of Boiler Functionality

- Impact of Water Purity on Boiler Performance

- Frequently Asked Questions About Boiler Efficiency and Water Quality

- What Does “Boiler Efficiency” Mean?

- How Do I Identify if Poor Water Quality is Impacting My Boiler’s Efficiency?

- Can I Use Ordinary Tap Water in Boilers?

- What is the Recommended Frequency for Checking Water Quality in Boiler Systems?

- What Are the Long-Term Consequences of Neglecting Water Quality in a Boiler System?

- In Conclusion

- Contact Point Bay Fuel for Comprehensive HVAC Solutions

Water is essential in boiler systems, used for heat transfer and distributing energy for heating or industrial uses. In steam boilers, water turns into steam for various applications.

A boiler system comprises key components like the burner, which ignites the fuel to produce heat transferred to the water via the heat exchanger. It also includes controls, safety mechanisms, and a flue stack for venting combustion by-products, ensuring efficient and safe operation.

Impact of Water Purity on Boiler Performance

The water used in boiler systems often contains various impurities that can detrimentally affect boiler efficiency. These include minerals like calcium and magnesium, commonly found in hard water, gases such as oxygen and carbon dioxide, various organic compounds from multiple sources, and suspended particles originating both internally and from external environments. Managing these contaminants is crucial for maintaining optimal boiler performance.

Formation of Scale and Its Consequences

Scale accumulation, resulting from minerals such as calcium and magnesium crystallizing and settling, is a significant concern in boiler systems. This results in:

- Creation of Scale: These minerals solidify and adhere to the surfaces within the boiler.

- Impaired Heat Transfer: The scale serves as a barrier, reducing the effectiveness of heat transfer.

- Risk of Tube Damage: The buildup of scale can cause obstructions in the tubes, potentially leading to damage.

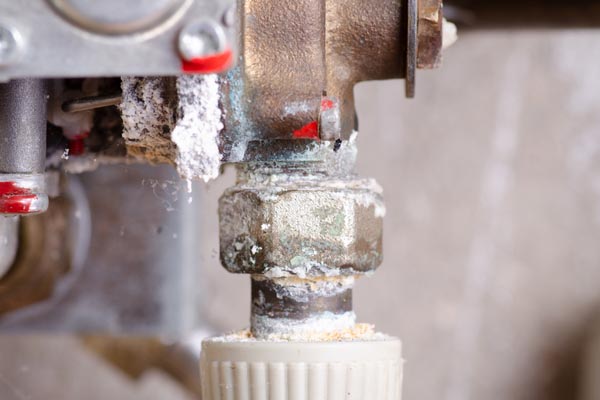

The Adverse Impact of Corrosion

Corrosion within boiler systems poses a major challenge, originating from factors like oxygen infiltration and imbalances in water pH levels. This corrosion can compromise the integrity of boiler components, posing threats to the system’s efficiency and safety. Moreover, problems stemming from corrosion typically decrease boiler efficiency, highlighting the critical need for timely intervention and management of these issues.

Issues of Foaming, Priming, and Carryover

Although less common, challenges such as foaming, priming, and carryover arise from elevated levels of impurities in the water, adversely impacting boiler efficiency. These issues typically lead to suboptimal steam quality, diminishing the system’s overall efficiency. Furthermore, complications like foaming and carryover can harm equipment located downstream from the boiler. This not only demands additional maintenance but also poses significant operational difficulties.

Boiler Water Treatment Strategies

Effective water treatment is key to maintaining boiler efficiency, beginning with initial treatment methods. These include filtration systems to remove particulate contaminants and suspended solids, softening and ion exchange processes to reduce water hardness by eliminating minerals like calcium and magnesium, deaeration and oxygen scavenging to remove dissolved gases and prevent corrosion, and pH balancing and alkalinity enhancement to maintain proper pH and alkalinity levels, helping to prevent corrosion and scale buildup.

In-Boiler Treatment Techniques

To further safeguard against efficiency deterioration and damage, internal treatment methods are utilized within the boiler system. These methods encompass:

- Scale Preventatives: Chemicals specifically formulated to inhibit scale formation on internal boiler surfaces.

- Corrosion Deterrents: Agents designed to shield the metal surfaces of the boiler from corrosive damage.

- Anti-Foaming Agents: Employed to minimize foaming within the boiler, which can adversely affect steam quality and efficiency.

- Dispersing Agents: These assist in distributing suspended particles evenly, thereby averting deposit accumulation.

Ongoing Surveillance and Automated Regulation Systems

Consistent management and monitoring of water quality are crucial for the long-term efficiency and safety of boiler systems. This involves regular checks to quickly identify and address water quality issues and the use of advanced technologies for accurate, automated control of water quality. These technological advancements significantly improve the maintenance of optimal water conditions, enhancing the efficiency and lifespan of boiler systems.

Advantages of Maintaining Optimal Water Quality in Boilers

Maintaining superior water quality in boilers yields numerous significant advantages, influencing the operational performance and safety of boiler systems.

- Enhanced Performance and Economic Benefits: Superior water quality in boilers leads to increased efficiency, less energy consumption, and cost savings. This is achieved by preventing issues like scaling and corrosion, which can impair heat transfer.

- Prolonged Equipment Service Life: Clean water usage in boilers reduces scale and corrosion, thus extending the life of boiler components and the overall system, reducing the need for frequent repairs and replacements.

- Decreased Maintenance Expenses and Operational Interruptions: Fewer water-related issues mean less frequent maintenance and a lower chance of system failures, resulting in decreased maintenance costs and fewer operational disruptions.

- Improvements in Operational Safety: Effective water treatment and management enhance the safety of boiler operations. Good water quality prevents hazardous conditions that could lead to leaks or explosions, ensuring a safer environment in both residential and industrial settings.

Frequently Asked Questions About Boiler Efficiency and Water Quality

What Does “Boiler Efficiency” Mean?

Boiler efficiency refers to the capability of a boiler to convert the energy contained in its fuel into usable heat. Generally, this efficiency is quantified as a percentage, indicating the proportion of the total energy in the fuel effectively converted into heat.

How Do I Identify if Poor Water Quality is Impacting My Boiler’s Efficiency?

Signs that inferior water quality compromises your boiler’s efficiency include diminished heating performance, escalated fuel usage, and unusual noises or operational behaviors. These signs often point to complications such as scaling, corrosion, or other water-related concerns within the boiler system.

Can I Use Ordinary Tap Water in Boilers?

Using tap water in boilers is feasible, but it might not always be the best choice. Tap water can contain various impurities, including minerals and chemicals, which can contribute to scaling and corrosion. These issues can negatively affect the efficiency and longevity of the boiler.

What is the Recommended Frequency for Checking Water Quality in Boiler Systems?

It is advisable to conduct water quality assessments regularly, with an ideal frequency being on an annual basis. These routine checks facilitate the early identification and remediation of any water-related issues that could impact the system’s efficiency.

What Are the Long-Term Consequences of Neglecting Water Quality in a Boiler System?

Over the long term, ignoring water quality in a boiler system can lead to several detrimental outcomes. These include a decline in efficiency, heightened repair and maintenance expenses, and a reduced operational lifespan of the boiler. Moreover, persistent neglect can pose significant safety risks, such as the possibility of leaks or catastrophic system failures.

In Conclusion

Proper water quality is key to maintaining boiler efficiency, prolonging equipment life, and ensuring safety. Emphasizing regular maintenance, vigilant monitoring, and effective water treatment safeguards boiler systems, boosts performance and avoids costly repairs, leading to economic and operational benefits.

Contact Point Bay Fuel for Comprehensive HVAC Solutions

Point Bay Fuel is your go-to provider for exceptional heating and cooling services in Ocean County and Monmouth County, New Jersey. Our team comprises highly skilled, professionally certified technicians adept at delivering top-notch HVAC maintenance, repairs, installations, replacements, and more. Each technician has the expertise and experience needed to service your HVAC system efficiently and effectively.

We pride ourselves on offering the region’s most competitive prices for heating and cooling services. Our maintenance solutions are designed to enhance comfort, boost energy efficiency, and lower heating and cooling expenses. In situations requiring HVAC repair or system replacement, Point Bay Fuel is ready to recommend the most suitable options for your home, ensuring they align with your budget.

We stand behind our work with a satisfaction guarantee as a testament to our commitment to quality. To arrange a service visit, contact Point Bay Fuel. We provide complimentary, in-home estimates. Call now to get started!

Contact us now by calling (732) 349-5059 to speak to one of our home comfort specialists! Click the link to view our service area.

Related Articles: